Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Feiyang

Type: Shearing Machine

Forging Forming Method: Mold Forging

Power Source: Hydraulic Pressure

Feature: Automation

Certification: ISO9001

Warranty: 24 Months

Customized: Customized

Advantage: Easy to Maintenance

Condition: New

Packaging: 1.main machine packed in plastic film. 2.hydraulic station and PLC control system in wooden box. 3.according to clients requirements. 4.color steel shutter door/door frame roll forming machine need one 40

Productivity: 100 set per month

Transportation: Ocean

Place of Origin: China,Hebei

Supply Ability: 100 set per month

Certificate: CE

Port: Tianjin Port

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB

The metal wall roof panel hydraulic decoiler body is a welded box-shaped structure, and the variable frequency speed regulating motor drives the reel shaft to provide the main power for the uncoiler after being decelerated by the gear box. The reel of the uncoiler is a hollow shaft supported by two bearings on the gear housing with a transmission spur gear mounted between the bearings. The gearbox is lubricated by forced lubrication and is equipped with two constant speed motors for the closed loop oil lubrication system. The mandrel is a cantilever structure whose front end is supported by an outer support bearing during unwinding to maintain the rigidity and stability of the uncoiler.

The uncoiler should be operated in strict accordance with the "opening machine operating procedures".

1. In the loading operation, a special person should cooperate with the forklift driver to make the steel coil material and the center of the expansion and contraction spool axis basically consistent, and then the forklift driver slowly puts the steel coil material on the trolley.

2. The operator should raise or lower (lifting the trolley) and adjust the coil material to the center of the expansion and contraction spool (ie, the material can enter the expansion and contraction shaft). At this time, adjust the movable bearing seat at the top of the uncoiler to make it The decoiler remains at the same level.

3. Adjust the expansion nut to make four arc plates and expand the steel coil material to avoid deformation and damage of the steel coil material during work.

4. When the steel coil material is inflated, turn the uncoiler by hand to observe whether the material rotates freely and avoid various hidden dangers in the work.

Our sheet metal bending machine can be profile custom,and are lower cost,high efficiency,reliable working ,low energy consumption.Any questions,please feel free to contact us.

Our Company

Our company is a manufacturer of Roll Forming Machine. We have been establishing and keeping good business relationship with more than 70 countries of worthy clients all over the world, mainly locating in East Europe, Middle East, South and West Asia, Africa and South America. We are proud of our own professional team with more than 18 years` experience in customized design and manufacture, installation and test, technical solution and after services. All the machines are with international quality standards and great after-sales services.

Main product catagories Color Steel Roll Forming Machine, classical glazed tile forming machine, Double Layer Roll Forming Machine,C/Z purlin machine for light steel structure building, floor deck forming machine, Sandwich Panel Production Line,fast guardrail roll forming line and various kinds full-automatic cold bending roll forming equipment.We do firmly believe :technological innovation ,making every detail of the product perfect is our ambition ever.

Any other questions please send inqury to us

Product Categories : Hydraulic Decoiler And Curving Machine > Hydraulic Decoiler

Home > Products > Hydraulic Decoiler And Curving Machine > Hydraulic Decoiler > metal wall roof panel hydraulic decoiler

Send Inquiry

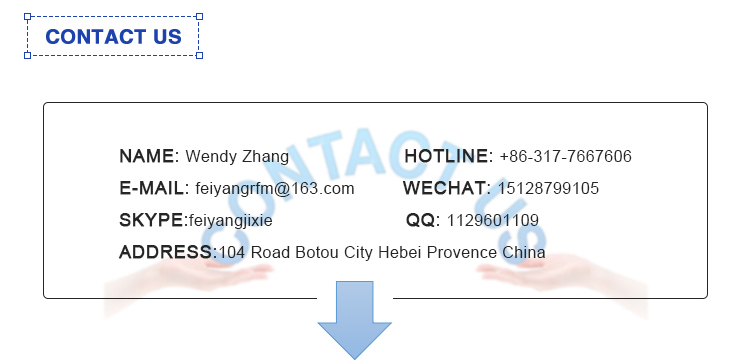

Ms. Wendy

Email:

Send Inquiry Tel:86-0317-7667606

Fax:0086-0317-7667606

Mobile Phone:+8615128799105

Email:

Address:Baozi Village,Nanxiakou Town,Dongguang County, Cangzhou, Hebei

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.